Tesla acronyms, abbreviations, terms and what they mean

WTTWOT! Or in plain English, Welcome To The World of Tesla! As you dip your toe in researching your much anticipated Tesla purchase online, or pull up for your first ever supercharge and strike up a conversation with the owner in the next (but one) stall, you’ll soon come across a new language: TWAs (Tesla World Acronyms). If you hadn’t stopped here, you might be scrabbling for words to keep up, but luckily you did stop here, and we’ve got you covered. You’ll be aware of some general EV (Electric Vehicle) and ICE (Internal Combustion Engine) abbreviations already, but if you want to know your SCs from your SuCs and more Tesla-specific TWAs, you’re in the right place.

Charging

CCS

Combined Charging System - a newer charging port that has become the standard in Europe and other markets

CHAdeMO

CHArge de MOve, a popular DC charging standard

J1772

AC power charging connection standard by SAE

MC

Tesla's Mobile Connector that was previously included with vehicles. Older generations are called the Universal Mobile Connector (UMC)

HPWC

Tesla's wall connector used to be called the High Power Wall Connector, but it is now just referred to as the Wall Connector

SC

OK, so this abbreviation comes up a lot in the Tesla community. And there are three possibilities with SC, so context is everything. SC can refer to the Service Center, which you hopefully won’t need. It can also refer to a SuperCharger in the Tesla network. Finally, it is occasionally used to refer to SolarCity, a solar energy company that was acquired by Tesla in 2016.

SuC

You might see this as an abbreviation for a Supercharger that helps to differentiate it from a Service Center.

SOC

State of Charge. The percentage your battery is charged.

PPU

Pay Per Use, for charging either at Superchargers or other public chargers

Electricity & Energy

AC

Alternating Current - the electricity in your house uses alternating current

DC

Direct Current - energy stored in batteries uses direct current

NEC

The National Electrical Code is a common standard for electrical wiring and equipment in the US

NEMA

The National Electrical Manufacturers Association is the largest association of electrical equipment in the US

NEMA 14-50

This common plug is often used to charge EVs and provides a maximum 50 amps of power, however EVs should only use up to 40 amps due to a constant load.

kW

Kilowatt (1000 watts, a unit of electric power)

kWh

Kilowatt-hours on the other hand refers to how much energy has been consumed in total. It is an absolute figure, equivalent to gallons or liters of gas burned in an ICE car.

Wh/mi

Not a Tesla-exclusive term, but an important one for EV owners. Watt-hours per mile is the EV equivalent of MPG, and tells us how much energy is being used per mile. Lower is better.

Regen

Again, an EV term rather than Tesla only, but you’ll see it used a lot in the Tesla community. It’s short for Regenerative Braking, and refers to the re-capture of kinetic energy by the battery when slowing down, or going down a steep hill. Regen is often the biggest thing new Tesla owners notice and have to adapt to. Once you do, there is no going back!

Computing Hardware

CPU

Central Processing Unit - the main chip in a computer responsible for processing data

GPU

Graphics Processing Unit - some computers contain a processor specifically made for rendering graphics

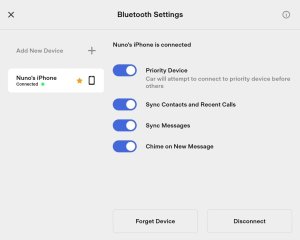

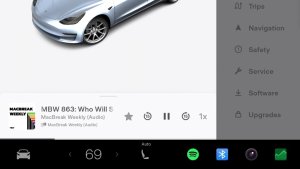

MCU

The Media Control Unit is the big touchscreen in the middle of the dashboard, and the computer that drives it. The car’s various radios, and all the entertainment and drive-related visualizations are routed through here. You may come across some numbers attached to MCU that specify the hardware version.

MCU1

MCU1 refers to Tesla's first Media Control Unit hardware which was used in Model S and Model X vehicles until March 2018

MCU2

This is Tesla's second general Media Control Unit hardware. It was used in Model S and Model X cars after March 2018. The Model 3 and Model Y started with MCU2 and later transitioned to MCU3 in late 2021. Vehicles with MCU1 can be upgraded to MCU2. MCU2 has the Intel Atom processor.

MCU3

This is Tesla's third and latest MCU hardware. It contains AMD Ryzen's chip, making it much faster than MCU2. For the Model S and Model X it also features a dedicated GPU that will be used for high quality games that rival the PS5 and Xbox Series X. There is no official word from Tesla yet, but MCU2 does not appear to be upgradeable to MCU3.

HW1

Hardware 1 refers to Tesla's original hardware for Autopilot. It was supplied by MobileEye and was only available on the Model S and Model X.

HW2

Around October 2016 Tesla transitioned to their own hardware with version 2.0. This was also only available for the Model S and Model X.

HW2.5

Hardware 2.5 was available in the Model 3 and the Model S and Model X around July 2017.

HW3.0

Tesla eventually released hardware 3.0 in April 2019, which features much faster processors. Owners who bought the FSD package (not the subscription) and had hardware 2.5 are given a free upgrade to hardware 3.0.

ECU

The Electronic Control Unit is the hardware in a vehicle used to control various driving functions.

eMMC

Embedded Multi Media Card is flash storage that is used to store certain information.

IC

An Integrated Circuit, is a chip that is integrated onto a circuit board. This could could refer to the Instrument Cluster on a Model S or Model X.

PCB

Printed Circuit Board used in electronic systems.

Driver Assistance System

DAS

Driver Assistance System, in Tesla's case this would be Autopilot

AP

Autopilot is the term that allows Tesla's to perform some level of self-driving. All Teslas today include basic Autopilot that allows the car to use TACC (Traffic-Aware Cruise Control) and Autosteer.

EAP

Enhanced Autopilot is a package that is a subset of FSD. Tesla offered it for a number of years, but it no longer offers it.

Enhanced Autopilot included features such as TACC (Traffic-Aware Cruise Control), Autosteer, Smart Summon, Autopark, automatic lane changes and more. It does not include as much as the FSD package, which allows the car to also navigate on city streets.

FSD

Full Self-Driving. Refers to the package that currently, in beta form, allows Teslas to navigate many more streets and scenarios by itself (with an alert and engaged driver on standby). In Europe and Asia FSD is still limited, but cars with the FSD package are ready to go from a hardware perspective as soon as the regulations allow.

TACC

Traffic-Aware Cruise Control - All Teslas today compare standard with TACC.

These are the Tesla acronyms and abbreviations you’ll encounter most often. Which ones are new to you? Have you come across any others?

Software

UI

UI stands for User interface, also commonly referred to as GUI (graphical user interface). You'll often find this term when referring to the design of a piece of software.

UX

UX is the User Experience of a piece of software.

OTA

OTA stands for Over-The-Air, referencing Tesla's ability to download car updates over Wi-Fi or in some cases using the vehicle's cellular data.

Single Stack

A technology stack refers to the technologies used to build a system. A single-stack refers to using the same technologies for multiple applications, instead of having separate technology stacks for each one. Single-stack is often mentioned regarding Tesla to applying everything it has learned in city driving to its Navigation on Autopilot highway feature.

Car Features

DRL

Daytime Running Lights are lights on your vehicle that remain on even during daylight.

IC

The Instrument Cluster on a Model S or Model X. This term could also mean Integrated Circuit which is a chip that is integrated onto a circuit board.

TPMS

A vehicle's Tire Pressure Monitoring System

HVAC

The Heating, Ventilation and Air Conditioning system in a home or vehicle

Governing Bodies & Agencies

EPA

Environmental Protection Agency

IIHS

Insurance Institute for Highway Safety (for safety ratings)

EU

European Union

NHTSA

National Highway Traffic Safety Administration - The U.S. federal government agency that governs vehicle safety.

SAE International

Formerly known as the Society of Automotive Engineers, it's a US-based association for developing standards for engineering professionals

Tesla / EV Terms

GF

GigaFactory - What Tesla calls their various factories, such as Giga Factory Texas

ICE

ICE refers to traditional gas and diesel-powered vehicles that contain an Internal Combustion Engine

ICEd

Being ICEd refers to an EV charging spot being taken up by an ICE vehicle

SA

Tesla's Service Advisors which are the main contact at Tesla Service

Investing

TSLA

TSLA is Tesla's stock symbol but the term is often used around someone investing in Tesla as well

TSLAQ

TSLAQ is pronounced "Tesla Q" and refers to individuals who publicly criticize Tesla and may be short-selling (the opposite of buying stock when profits are earned when the stock goes down) Tesla stock

FUD

FUD stands for Fear, Uncertainty, and Doubt and is sometimes used when someone is spreading misinformation to cast fear

Batteries

LFP

This is referring to the battery chemistry in the car’s high voltage pack, specifically the chemical symbols for Lithium (L), Iron (F) and Phosphate (P is actually for Phosphorus on its own, but PO₄³⁻ doesn’t have the same ring to it). Tesla started shifting some of its shorter-range cars (the SR MYs and M3s) to LFP in 2021, away from battery chemistry involving Nickel and Cobalt.

Even if you’re not a chemist, it’s still worth knowing which battery chemistry you have. It is recommended to keep LFP battery charge limit at 100%, unlike the previous Li-ion batteries that are stressed out if charged fully too often.

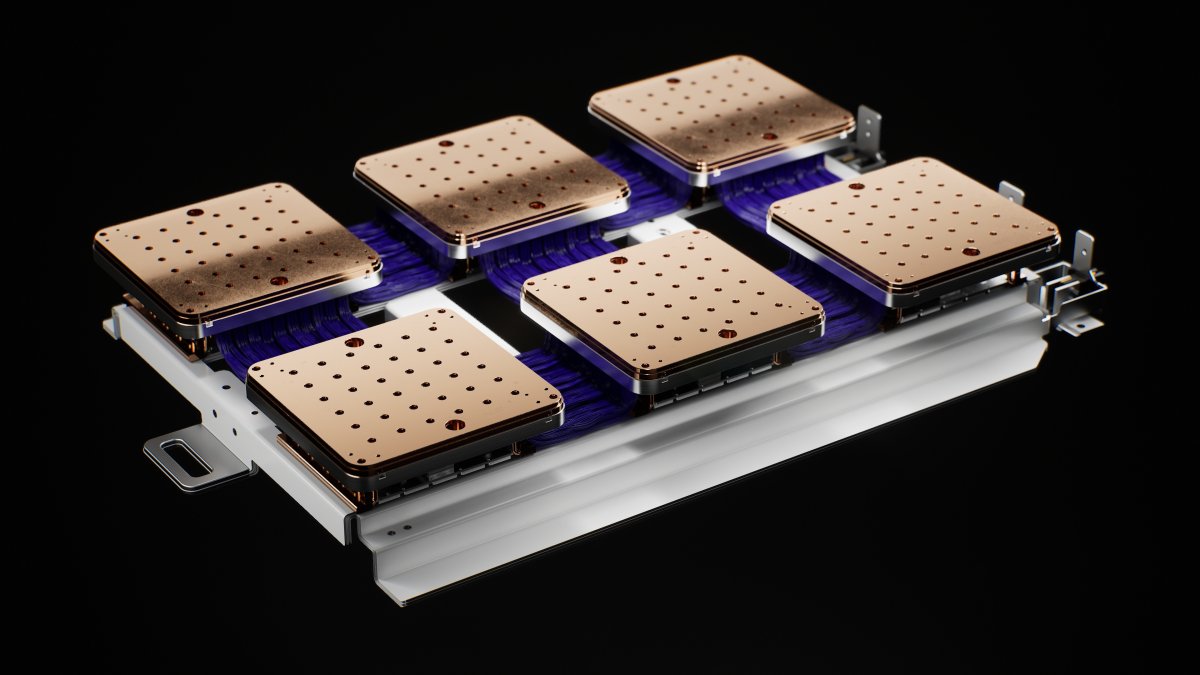

4680

Staying with the high voltage battery, 4680 refers to the newer battery technology that is being phased in at Giga Berlin, Giga Texas and Giga Shanghai. These batteries offer efficiency, range and cost improvements over the previous, smaller batteries. The numbers come from the dimensions of each individual cell: 46 x 80mm.

Tesla Models

SR

Standard Range. For example, a M3SR refers to the Model 3 Standard Range model.

SR+

The Standard Range Plus variant has a larger battery than the Standard Range and some additional features.

MR

Mid Range vehicle which was available for the Model 3 (discontinued)

LR

Long Range model which includes a larger battery than other variants. For example, a M3LR refers to the Model 3 Long Range model.

P

Performance model. This could refer to the performance model of any Tesla vehicle.

P3D

The performance variant of the Model 3 dual motor

P3D+

Performance Model 3. This term was used when Tesla offered the Model 3 with and without the additional performance hardware such as larger wheels and disc brakes and a spoiler. This model is commonly referred to as the P3D.

P3D-

The performance Model 3 without all the features in the P3D+

M3P

The same as P3D

MY

Simply referring to the Tesla Model Y

MX

Model X

MS

Model S

M3

Model 3

CT

Cybertruck

Motors & Drives

DM

DM refers to a Dual Motor vehicle

AWD

All Wheel Drive - In a Tesla, this means that at least two motors are powering the vehicle. Some cars contain two rear motors and a single front motor, while all Model 3s and Model Ys will contain a single front and rear motor.

RWD

RWD refers to the car being a rear-wheel drive vehicle. In Teslas that means that there's a single motor in the back powering the car.

Alternatively, you might see a M3RWD (Model 3 Rear Wheel Drive).

General Information

EV

Electric Vehicle

PHEV

Plug-in Hybrid Electric Vehicle (ICE/EV combo)

LHD

Left-hand drive

RHD

Right-hand drive, as used in Australia, England and Japan

OEM

Original Equipment Manufacturer

Artificial Intelligence

NN

Neural Network refers to AI and is a subset of Machine Learning (ML) that Tesla uses to develop Autopilot

![No Driver Needed: Tesla FSD Stops at Toll, Waits for Driver to Pay and Takes Off Again [VIDEO]](https://www.notateslaapp.com/img/containers/article_images/fsd-beta/fsd-toll-booth.webp/57e008aff60c6c1e998e304eca200cda/fsd-toll-booth.jpg)

_300w.png)